Core Expertise

Oem manufacturing for

Laser

System Design

This is where we shine. Our expertise in laser illumination coupled with our award-winning team has culminated in the release of an OTF laser launch that cannot be beat for value. Let us apply our knowledge and ingenuity to your problem.

Oem manufacturing for

Custom

Illumination

Design

Your application depends on precisely the right light delivery. We have the expertise to help you find the right illumination solution to deliver the results you need.

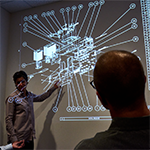

Custom Engineering Solutions

Oem manufacturing for

Optical System

Design

Manipulation and management of light is inherently challenging. 89 North seeks simple solutions to complex challenges wherever possible, while balancing cost, schedule, and risk.

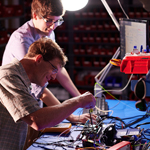

Oem manufacturing for

Design To

Manufacture

Services

Experience the advantage of working with a small and dedicated team of award-winning engineers to realize your custom solution.

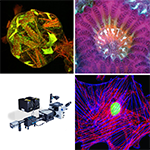

Commercial Applications

Oem manufacturing for

Bioanalytical

Device

Manufacturing

89 North understands there is more to an optics system than just shining a light. We optimize every aspect of the design with the objectives of simplicity, cost-effectiveness, efficiency, and elegance.

Oem manufacturing for

Photonics &

Imaging

89 North optimizes the excitation and emission pathways, reduces the noise, and maximizes the signal - getting every photon that counts to the detector.

Oem manufacturing for

Technical

Collaboration

Process

89 North is as comfortable building a multiphase laser controller as we are designing the optics for flat-field illumination: We welcome the challenge.

Oem manufacturing for

Industrial

Inspection

Elegance in simplicity. We understand complexity, but seek out the best, simplest, most cost-effective solution to your industrial inspection needs.